Access Agilent eNewsletter January 2016

Chevron and Agilent collaborate on new multi-element crude oil analysis technology that delivers advantages in speed, cost, and safety

Wayne Collins, Agilent Global Industry Manager

Elemental concentrations in crude oil are vitally important to the petroleum industry throughout the entire supply chain. Metal types and concentrations are used to monitor crude migration within a reservoir and are a factor in determining the market price of a batch of oil. They also affect the efficiency of catalysts during refining and are integral to final product quality. What’s more, metal profiles are also instrumental in “fingerprinting” oil during an environmental incident to identify the source and to monitor the effectiveness of remediation efforts.

Laboratories have used several technologies for measurements of metal types and concentrations. Now, Agilent has partnered with Chevron [1] to add another technology, microwave plasma atomic emission spectroscopy (MP-AES), as it is increasingly used for the multi-element analysis of a wide range of sample types.

MP-AES technique delivers lower operation costs and improved safety

The Agilent 4200 MP-AES uses magnetically coupled microwave energy to generate robust and stable plasma using nitrogen gas from the air. This eliminates the need for expensive argon or flammable gases, such as acetylene. Lower cost operation and improved safety are top priorities for all petroleum laboratories. Generating the plasma from air is also a big plus for petroleum companies that must support labs in remote regions of the world where sustainable gas supplies can be limited.

Employing the 4200 MP-AES, Chevron and Agilent analyzed 20 crude oil samples with API gravity 7 to 38°, with a range of nitrogen and sulfur contents. A fast and easy method with minimal sample preparation was the goal. The method comprised a simple 〜 1:10 dilution in o-xylene containing mineral oil, a matrix modifier, and scandium as the internal standard. The elements were limited to V, Ca, Fe, Ni, K, and Na, though others are possible.

More sensitive calibrations and lower detection limits

The results of the analysis showed improved calibrations and lower detection limits. The calibration curves obtained for all elements indicated excellent linearity over the calibration range with correlation coefficients from 0.99988 to 1.0000. Method detection limits (3σ) were calculated by measuring a blank solution 10 times and then by measuring a 1 ppm standard solution 10 times. The MDLs were comparable for all elements by both methods and were well into the sub ppm range.

Good recoveries validated in spiked sample tests

During the testing, at the midpoint concentration of the calibration (5 ppm), a continuing calibration verification sample was analyzed seven times. Next a crude oil sample was spiked with the mixed standard at 885 ppm to validate the method at high concentration. Finally, certified reference sample NIST 1634c Trace Elements in Fuel Oil was analyzed seven times for V (certified 28.19 ppm) and Ni (certified 17.54 ppm) only. In all three tests, recoveries were within ±10%.

Improved test results for crude oil samples

Table 1 shows results achieved when the method was used to determine elements in 20 crude oil samples.

| Sample | Fe | SD | V | SD | Ni | SD | Ca | SD | Na | SD |

|---|---|---|---|---|---|---|---|---|---|---|

| 259.940 nm | 311.070 nm | 341.476 nm | 396.847 nm | 588.995 nm | ||||||

| ppm | ppm | ppm | ppm | ppm | ||||||

| S1 | 0.46 | 0.13 | 13.86 | 0.03 | 9.51 | 0.05 | LDL | - | LDL | - |

| S2 | 0.48 | 0.02 | 132.42 | 0.39 | 33.61 | 0.06 | LDL | - | LDL | - |

| S3 | 1.98 | 0.03 | 2.14 | 0.02 | 2.42 | 0.03 | 2.04 | 0.01 | 0.52 | 0.13 |

| S4 | 8.99 | 0.14 | 225.88 | 0.27 | 59.55 | 0.12 | 0.70 | 0.01 | 11.13 | 0.42 |

| S5 | 0.55 | 0.04 | 2.09 | 0.02 | 0.81 | 0.06 | 0.06 | 0.00 | LDL | 0.08 |

| S6 | 26.02 | 0.14 | 115.09 | 0.10 | 87.45 | 0.28 | 13.97 | 0.59 | 15.62 | 0.15 |

| S7 | 23.52 | 0.11 | 39.12 | 0.13 | 68.56 | 0.13 | 1.09 | 0.09 | 2.35 | 0.11 |

| S8 | 0.01 | 0.04 | 15.88 | 0.08 | 12.79 | 0.01 | LDL | - | LDL | - |

| S9 | 0.25 | 0.03 | 24.50 | 0.05 | 12.40 | 0.05 | LDL | - | LDL | - |

| S10 | 9.65 | 0.57 | 0.13 | 0.03 | 0.87 | 0.03 | 5.05 | 0.33 | 5.99 | 0.39 |

| S11 | 13.38 | 0.25 | 6.02 | 0.04 | 5.19 | 0.05 | 4.99 | 0.08 | 18.57 | 0.61 |

| S12 | 0.81 | 0.08 | 0.79 | 0.02 | 1.23 | 0.04 | 0.21 | 0.01 | 0.74 | 0.05 |

| S13 | 1.27 | 0.06 | 2.19 | 0.01 | 1.60 | 0.01 | 0.25 | 0.01 | 0.65 | 0.09 |

| S14 | 1.21 | 0.05 | 59.63 | 0.29 | 20.67 | 0.03 | 0.87 | 0.01 | 4.54 | 0.06 |

| S15 | 2.17 | 0.05 | 177.45 | 0.58 | 35.86 | 0.22 | 5.97 | 0.02 | LDL | 0.04 |

| S16 | 11.89 | 0.23 | 2.57 | 0.02 | 4.56 | 0.04 | 4.01 | 0.02 | 44.36 | 1.56 |

| S17 | 0.24 | 0.05 | 24.83 | 0.09 | 12.63 | 0.03 | LDL | - | LDL | - |

| S18 | 0.07 | 0.05 | 18.80 | 0.10 | 12.02 | 0.03 | LDL | - | LDL | - |

| S19 | 10.47 | 0.73 | 71.05 | 0.57 | 28.09 | 0.19 | 2.43 | 0.09 | 8.39 | 0.58 |

| S20 | 130.99 | 1.05 | 87.48 | 0.21 | 68.08 | 0.18 | 58.29 | 0.27 | 26.59 | 0.41 |

| *S20b | 130.81 | 0.86 | 87.08 | 0.32 | 68.15 | 0.06 | 59.43 | 0.62 | 25.89 | 0.22 |

*Duplicate S20 sample

LDL—below the limitation of detection

Table 1. Measured concentrations of metallic impurities in 20 crude oil samples (mg/kg, ppm). [1]

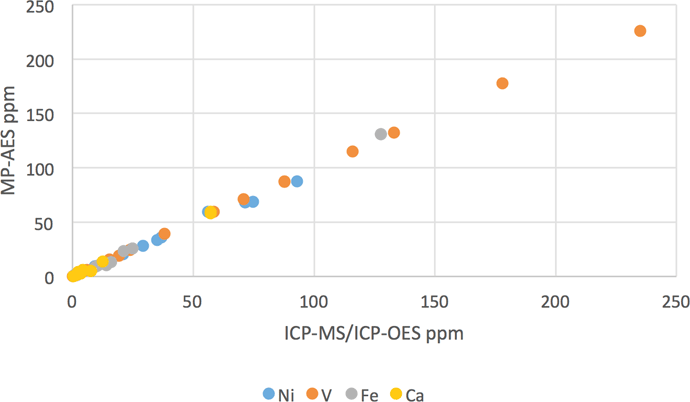

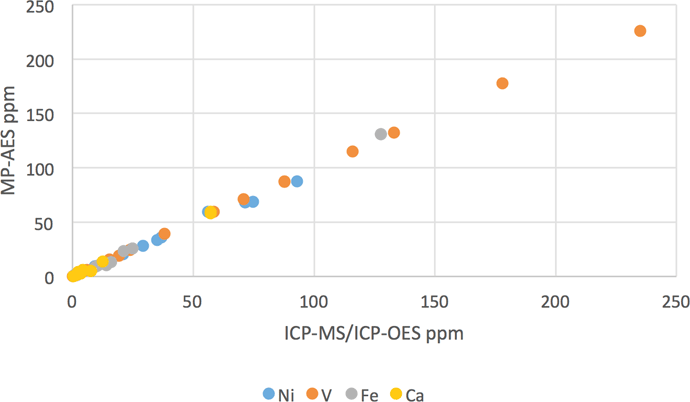

Figure 1. Comparison of measured values for crude oil samples obtained using a combination of ICP-MS and ICP-AES, and MP-AES.

Comparison of sample analysis methodologies

The same 20 crude oil samples were also analyzed by ICP-MS or ICP-OES to demonstrate comparability with these established technologies. Figure 1 shows a good correlation between the techniques. More information on this comparison of analysis techniques can be found in the August 2015 issue of Energy & Fuels [1].

Agilent and Chevron: partners for success

Chevron and Agilent demonstrated that MP-AES is a viable alternative to other methods for the elemental analysis of crude oil, while offering advantages in speed, cost, safety, and ease of preparation. A draft ASTM standard has been written based on this work and will be proposed at a meeting of section D02.03. Agilent has many analytical solutions for refinery operations, all backed by an industry-leading portfolio of supplies. Visit the Agilent web site today to learn more about our MP-AES systems and offerings.

Reference

- Nelson, J.; Gilleland, G,; Poirier, L.; Leong, D.; Hajdu, P.; Lopez-Linares, F. Elemental Analysis of Crude Oils Using Microwave Plasma Atomic Emission Spectroscopy. Energy & Fuels, 10 August, 2015. Reprinted with permission.

Stay informed about the applications that are important to you

Subscribe to Access Agilent

Our free customized

monthly eNewsletter

Article Directory – January 2016

All articles in this issue

What is in your beer? Find out using a Agilent J&W DB-624 Ultra Inert (UI) column with GC/MS static headspace solution

What is in your beer? Find out using a Agilent J&W DB-624 Ultra Inert (UI) column with GC/MS static headspace solution Moving biologics to market with automated biopharma workflow solution

Moving biologics to market with automated biopharma workflow solution Nobel Prize-winning lab uses Agilent equipment to accelerate natural product discoveries

Nobel Prize-winning lab uses Agilent equipment to accelerate natural product discoveries Tip: How to detect leachables from drug container closures in pharmaceutical products

Tip: How to detect leachables from drug container closures in pharmaceutical products Fast, accurate absolute-quantification of proteins and antibodies with Agilent 8800 ICP-QQQ

Fast, accurate absolute-quantification of proteins and antibodies with Agilent 8800 ICP-QQQ Chevron and Agilent collaborate on new multi-element crude oil analysis technology that delivers advantages in speed, cost, and safety

Chevron and Agilent collaborate on new multi-element crude oil analysis technology that delivers advantages in speed, cost, and safety Ask the Expert: Can I improve the chromatography of basic compounds on my older HPLC systems?

Ask the Expert: Can I improve the chromatography of basic compounds on my older HPLC systems? More pesticides identified using Agilent Pesticide DRS Screening GC/MSD Analyzer with new high efficiency source

More pesticides identified using Agilent Pesticide DRS Screening GC/MSD Analyzer with new high efficiency source Improved peak shapes for active semivolatiles with inert Agilent J&W DB-UI 8270D columns

Improved peak shapes for active semivolatiles with inert Agilent J&W DB-UI 8270D columns

Figure 1

Comparison of measured values for crude oil samples obtained using a combination of ICP-MS and ICP-AES, and MP-AES.